· UNDERSTANDING THE OPERATIONAL CHALLENGES OF INDSUTRIAL PRODUCTS

Main challenges

Optimizing your supply chain

You need to implement a Supply Chain strategy that fits your company goals, and navigate new market realities like new tariffs, shortages, transport disruptions, etc.

To achieve this, you need to rely on a senior team (which you may not have) or external consultants (who are often out of budget), while your team struggles to find the time to work on the strategy and implement it effectively.

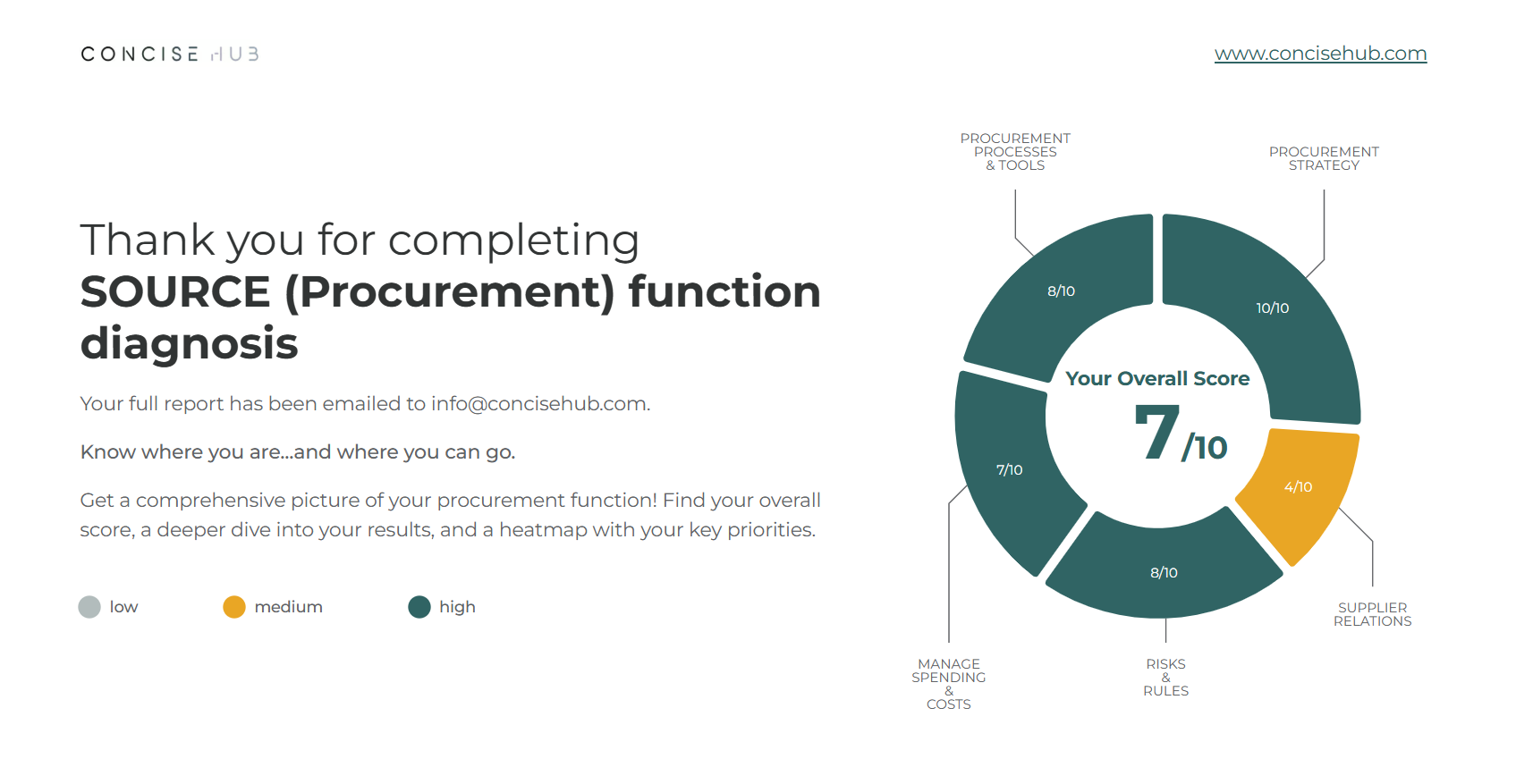

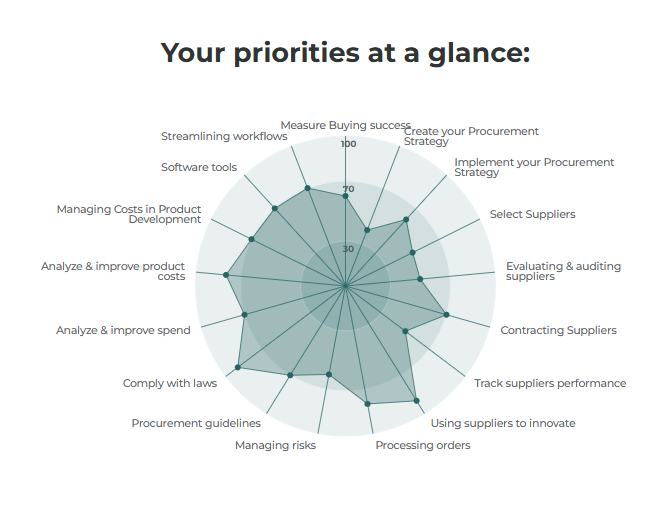

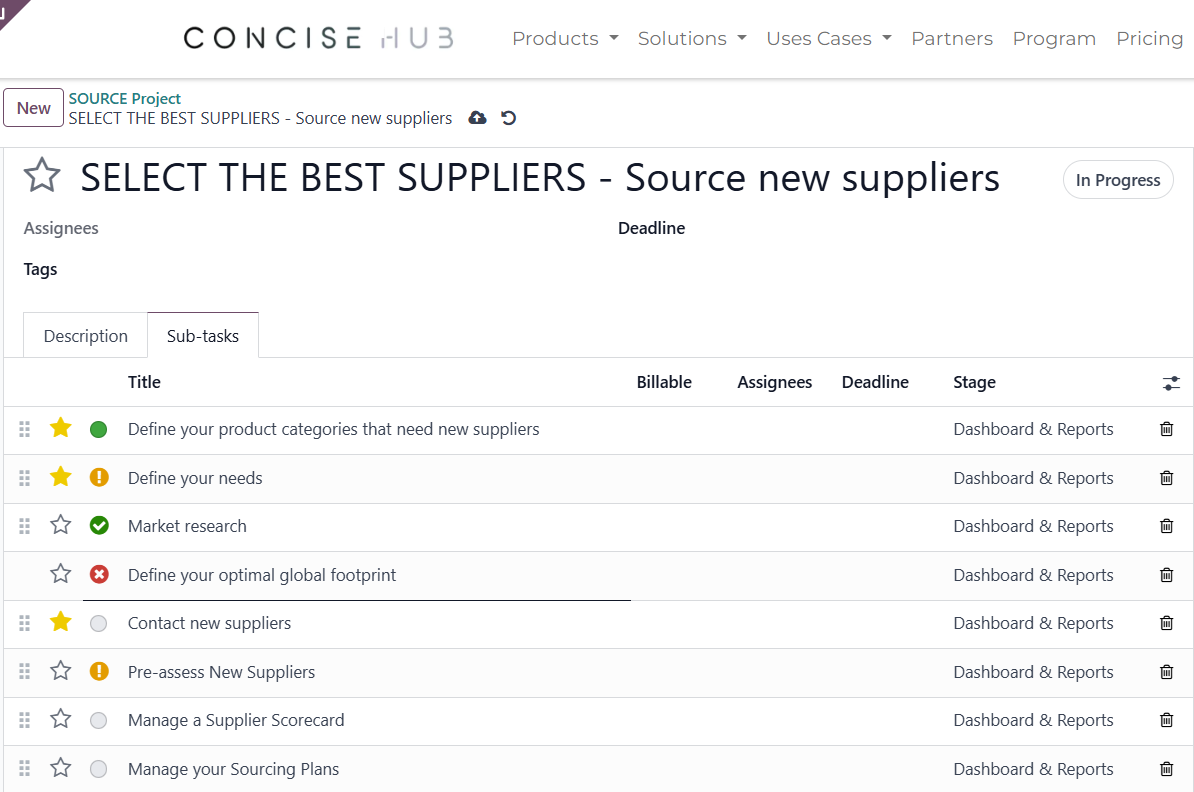

Supplier management

Supplier performance (quality, cost, delivery, service, innovation support) is critical for meeting online customer expectations.

Your team might not always use best practices to select, negotiate, onboard, and manage suppliers, a common practice in larger organizations.

This can be due to a lack of experience, limited access to the right frameworks, or missing a clear overview of all the moving parts involved in procurement management.

Inventory mgmt, warehouse & fulfillment

Planning inventory ad hoc, without following the correct frameworks, stresses your cash flow, increases inventory costs, and risks excess stock.

Overlooking 3PL requirements or being unaware of negotiation options with 3PLs risks inventory availability, customer satisfaction, and increases costs.

Your team might not use the same approach as large enterprises do for planning and managing your 3PLs due a lack of easy access to experienced professionals or resources.

Implementing changes

Implementing changes to improve your supply chain can go wrong when:

• You define the wrong strategy to achieve your company goals.

• You lack a roadmap to implement the needed changes.

• The team lacks the resources, focus, or visibility to push through and implement the changes.

• Team cross-functional collaboration is not effective.

· OPERATIONS TEAMS SUPPORT TO INDUSTRIAL OPERATIONS

How Concise Hub helps industrial applications companies?

· WHAT YOU GET

The result

Time & money saved

- Reduce consulting costs by up to 80%

- Cut assessment time from weeks to hours

- Increase your productivity by up to 40%

- Develop your team and enhance cross-functional collaboration

Faster & impactful transformations

- Rapid & automated diagnostics + benchmark against industry peers

- Streamlined cross-functional team tracking, reporting and collaboration

- Expertise gap bridged with countinuous team development

Customer experience

- Enhanced customer satisfaction and brand loyalty through superior operational execution

- Increased fulfillment accuracy, delivery speed, and responsiveness

Supplier management

- Best practices used to select, negotiate, onboard, and manage suppliers

- Improved supplier performance (quality, cost, delivery, service, innovation support)

- Reduced total cost of ownership

Inventory & availability

- Improved product availability

- Improved cash flow

- Reduced inventory costs

Warehouse & fulfillment

- Better understandiong of the 3PLs requirements and negotiation options

- Lower fulfillment costs, improve order accuracy, and accelerate delivery times, leading to enhanced customer satisfaction.

· OUR CLIENTS

Proud to work with

Level up your operations!

Design, produce, and sell physical products faster, more efficiently, and with less risk.